Low Carbon

When choosing a material for your project, remember that the use of local natural stone has the lowest of all carbon footprints when compared to all other construction and manufacturing materials. Valentia Slate is collaborating with researchers at Technical University Dublin to carry out a Life Cycle Analysis of the use of local natural stone, as opposed to manufactured construction materials, in construction. The last 100 years has seen a drift away from local stone in construction and almost all local dimension stone producers have disappeared. However, in the search for low carbon building methods and local provenance, this trend is set to be reversed and Valentia Slate is leading the way in research.

All the slate that we will ever sell is already made!

Valentia Slate is a naturally occurring rock – it is not manufactured like many composite materials (e.g. Silestone or Dekton often referred to as “quartz” worktops or panels). We simply take the slate out of our mine in Valentia and shape it into the product that you will use. There is no mixing, baking, rolling or use of high pressure machinery to manufacture a fake “rock”– our material has been there for 385 million years ago and we just cut and finish it to your specifications.

Low Carbon

When choosing a material for your project, remember that the use of local natural stone has the lowest of all carbon footprints when compared to all other construction and manufacturing materials. Valentia Slate is collaborating with researchers at Technical University Dublin to carry out a Life Cycle Analysis of the use of local natural stone, as opposed to manufactured construction materials, in construction. The last 100 years has seen a drift away from local stone in construction and almost all local dimension stone producers have disappeared. However, in the search for low carbon building methods and local provenance, this trend is set to be reversed and Valentia Slate is leading the way in research.

All the slate that we will ever sell is already made!

Valentia Slate is a naturally occurring rock – it is not manufactured like many composite materials (e.g. Silestone or Dekton often referred to as “quartz” worktops or panels). We simply take the slate out of our mine in Valentia and shape it into the product that you will use. There is no mixing, baking, rolling or use of high pressure machinery to manufacture a fake “rock”– our material has been there for 385 million years ago and we just cut and finish it to your specifications.

No raw materials

We therefore do not have suppliers who manufacture raw materials for us (e.g. composite worktop manufacturers must buy a plastic resin manufactured by others for making a worktop) and this cuts out the entire manufacturing and transport chain for raw materials.

We use green energy

Most of our machinery is electric as opposed to being powered by fossil fuels and our electricity supplier sells 100% renewable energy to us.

No waste

All of the slate that we quarry is used for some useful purpose and we are also recycling the waste from the old spoil heaps of the 1800’s. We do our best to make high value products from all of the material that is or was quarried in Valentia. This is best for local jobs and the local economy.

No raw materials

We therefore do not have suppliers who manufacture raw materials for us (e.g. composite worktop manufacturers must buy a plastic resin manufactured by others for making a worktop) and this cuts out the entire manufacturing and transport chain for raw materials.

We use green energy

Most of our machinery is electric as opposed to being powered by fossil fuels and our electricity supplier sells 100% renewable energy to us.

No waste

All of the slate that we quarry is used for some useful purpose and we are also recycling the waste from the old spoil heaps of the 1800’s. We do our best to make high value products from all of the material that is or was quarried in Valentia. This is best for local jobs and the local economy.

A real product

Slate is a completely natural product of the Earth and has not been processed in any way apart from shaping for your use. Manufactured “stone” used commonly in worktops and cladding is a fine material and is commonly called “ceramic granite” or “quartz”. These materials can be made to imitate any natural or imagined stone but are commodities and have no provenance.

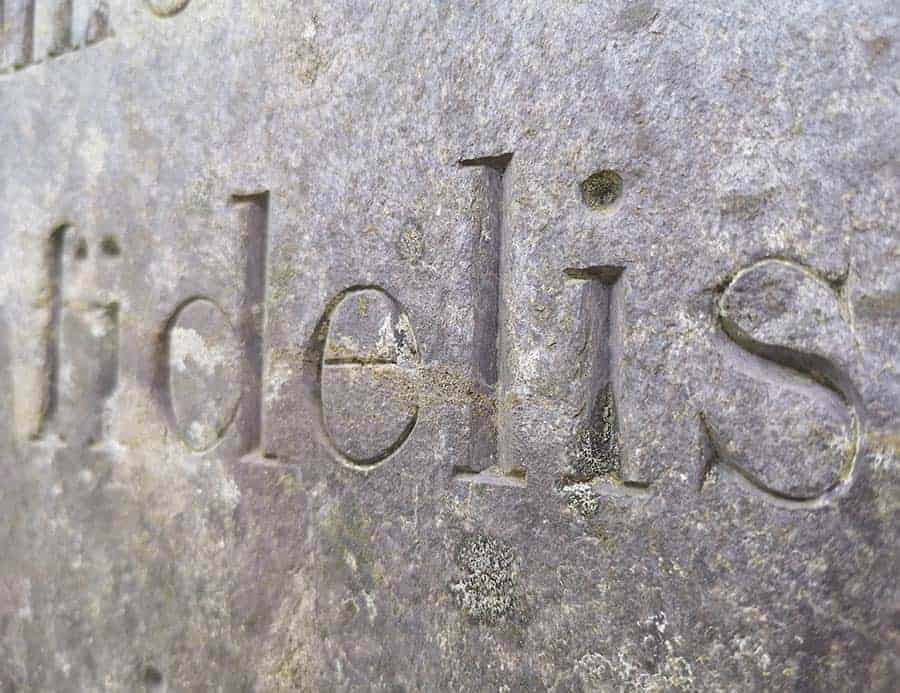

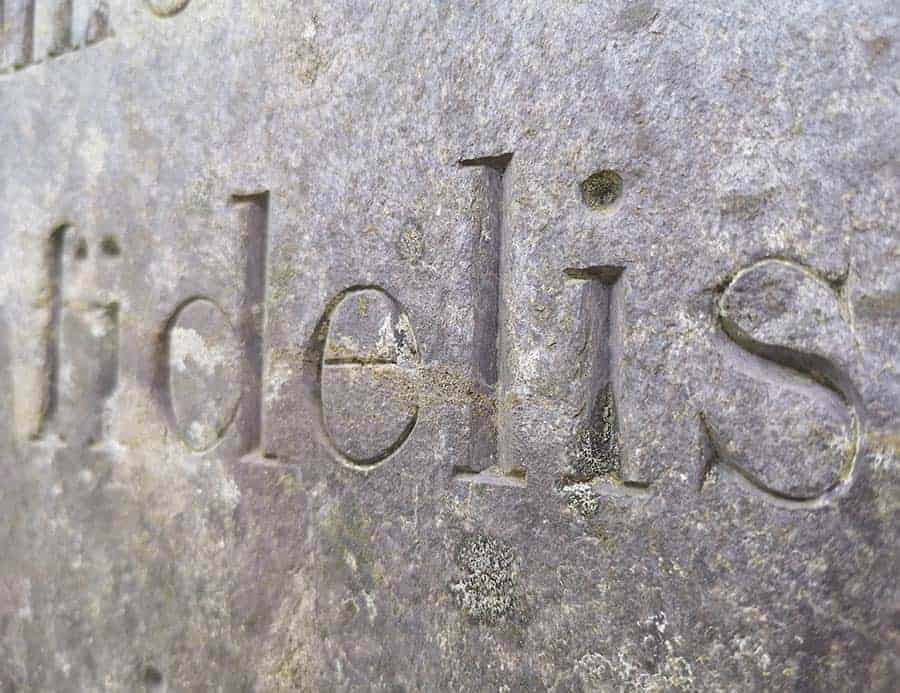

A strong and durable product

Valentia Slate ideal for projects where a very long service life is envisaged. It is stronger and more resistant to the elements than any other stone available, natural or man-made. It will outlast any building that it is used in.

A local product

In general, it is better from an environmental and jobs perspective to use local products. Transport accounts for a significant proportion of the environmental cost of stone products, particularly if transported halfway around the world. In many cases, stone is transported from a quarry on one continent to a processing facility on another and then the finished product is sent to another. This adds up in carbon terms but the carbon cost is very low if quarrying and processing and dispatch all occur at the same location. At Valentia Slate, all of these steps take place on Valentia Island and are carried out by local staff.

A real product

Slate is a completely natural product of the Earth and has not been processed in any way apart from shaping for your use. Manufactured “stone” used commonly in worktops and cladding is a fine material and is commonly called “ceramic granite” or “quartz”. These materials can be made to imitate any natural or imagined stone but are commodities and have no provenance.

A strong and durable product

Valentia Slate ideal for projects where a very long service life is envisaged. It is stronger and more resistant to the elements than any other stone available, natural or man-made. It will outlast any building that it is used in.

A local product

In general, it is better from an environmental and jobs perspective to use local products. Transport accounts for a significant proportion of the environmental cost of stone products, particularly if transported halfway around the world. In many cases, stone is transported from a quarry on one continent to a processing facility on another and then the finished product is sent to another. This adds up in carbon terms but the carbon cost is very low if quarrying and processing and dispatch all occur at the same location. At Valentia Slate, all of these steps take place on Valentia Island and are carried out by local staff.